Basic HTML Version

10

MECHANICAL ENGINEERING – LOCATIONS –

TECHNOLOGY & PRODUCT DEVELOPMENT

– NEWS AND INFORMATION

PRODUCTS

uel consumption, environmental

friendliness and safety are key as-

pects when buying a car. However, an-

other very important consideration for

purchasing a new vehicle is the comfort

for both driver and passengers alike.

Therefore, SCHERDEL has, for many

years now, been developing outstand-

ing solutions for the automotive industry

in cooperation with car makers that pay

great attention to user comfort and con-

venience. A prime example is the ten-

sion spring mechanism, which has

been further developed into an assem-

bly part to facilitate the opening and

closing of car tailgates. Seen from the

viewpoint of OEMs, the SCHERDEL

developments are comfort solutions

which do not add a great deal to the

price of production. SCHERDEL sup-

plies roughly 6.5 million tension spring

mechanisms for worldwide use each

year.

It is quite easy to explain why

SCHERDEL has gone from being a

leading manufacturer of “simple” ten-

sion springs to a supplier of functional

groups for the opening and closing of

tailgates. On the one hand, it is

SCHERDELʼs extensive knowledge of

materials and production processes

which play a decisive role in product

development using cutting-edge simula-

tion tools. On the other hand, in addi-

tion to a highly motivated workforce,

SCHERDEL has the technical means to

develop system solutions and to pro-

duce them “from a single source”. And

the exciting and creative synergies

within the Group with its own mechani-

cal engineering and tool making divi-

sions and state-of-the-art coating instal-

lations should not be forgotten. Modern-

day tailgate opening systems are actu-

ally based on a former trend: the com-

bination of a bracket hinge and a tor-

sion spring guarantees the

automatic opening of the

tailgate no matter which

external conditions prevail.

Once application of the

correct material has been

determined, product devel-

opment initially involves

calculation of the required

manual force curve togeth-

er with the design of the

ideal spring. SCHERDEL

was able to develop a ma-

terial which has since been

patented and prevents hy-

drogen embrittlement dur-

ing the painting process,

thus ensuring the desired service life of

the springs. Further criteria for success-

ful product development were the FEM

calculations for optimizing the rigidity

and weight of the opening systems and

achievement of the corrosion resistance

desired by the customers.

It is possible to assemble SCHERDEL

tailgate torsion springs before painting.

The joint dimension can be determined

during installation, thus helping to re-

F

Tension springs – a notice

Patented material from SCHERDEL used for the co

opening and closing systems

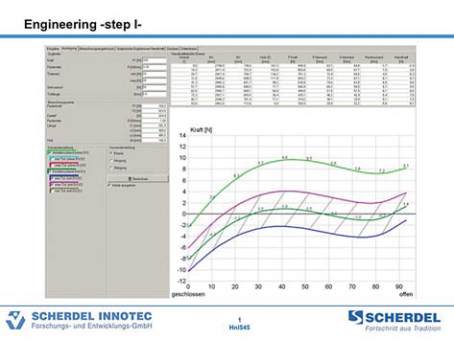

Calculation mask: theoretical pre-

diction of manual force curve, ten-

sion spring mechanism for opening

car tailgates

Start model for analysis of the stress curve using

the Finite Element Method (FEM)

Contact data

SCHERDEL INNOTEC

Forschungs- und Entwick-

lungs-GmbH

Scherdelstr. 2

95615 Marktredwitz

Germany

Contact:

Dipl. Ing. Thomas Heinl

Tel.: +49 9231 603-545

Email:

thomas.heinl@scherdel.de

Company anniver-

sary

The SCHERDEL factory in Er-

langen recently celebrated its

75th anniversary. Plant manager

Johann Kerner welcomed the

principal shareholder of the

SCHERDEL

Group

, Heidelore

Scherdel, as well as the Group

managing director, Walter Bach,

and the shareholder Marcus

Bach to Erlangen on the occa-

sion of this special anniversary.

Manfred Wegmann, Thilo von

Glass, Josef Söllner and Eber-

hard Leidl had also been invited

as representatives of the

SCHERDEL management. The

subsidiary in Erlangen-Bruck was

founded in 1936 by Max and Ru-

di Scherdel. Initial products in-

cluded valve springs for aircraft

engines. The company later fo-

cused on the production of

springs for mattresses and the

manufacturing of double-body

springs.

Today, the SCHERDEL plant in

Erlangen primarily produces high-

loaded tension springs for appli-

cation in various industry sectors.